Levels are widely used in construction, engineering, home improvement, carpentry and other fields, and its market status is as follows:

Regional Market Patterns: In terms of geography, Asia-Pacific accounted for a large sales market share of 41% in 2023, followed by Europe and North America. Asia Pacific is expected to be the fastest growing market during the forecast period due to its wide adoption in the construction and renovation sector, with China, in particular, contributing significantly to global sales and revenue generation.

Product Type Development: The rise of digital and electronic levels with higher accuracy, ease of use, and additional features such as angle measurement, vibration alerts, and Bluetooth integration is attracting professionals looking for more advanced tools, and these products are gaining market share.

Demand by application: Leveling tools are in demand in the construction and renovation (both residential and commercial sectors), metal and wood working, DIY and other sectors. Expansion of the construction industry is a key driver, with demand for leveling tools increasing due to the rise in new buildings, infrastructure projects, and renovations. Meanwhile, growing interest in home improvement and DIY projects, especially in developed markets, is also leading to increased sales of leveling instruments.

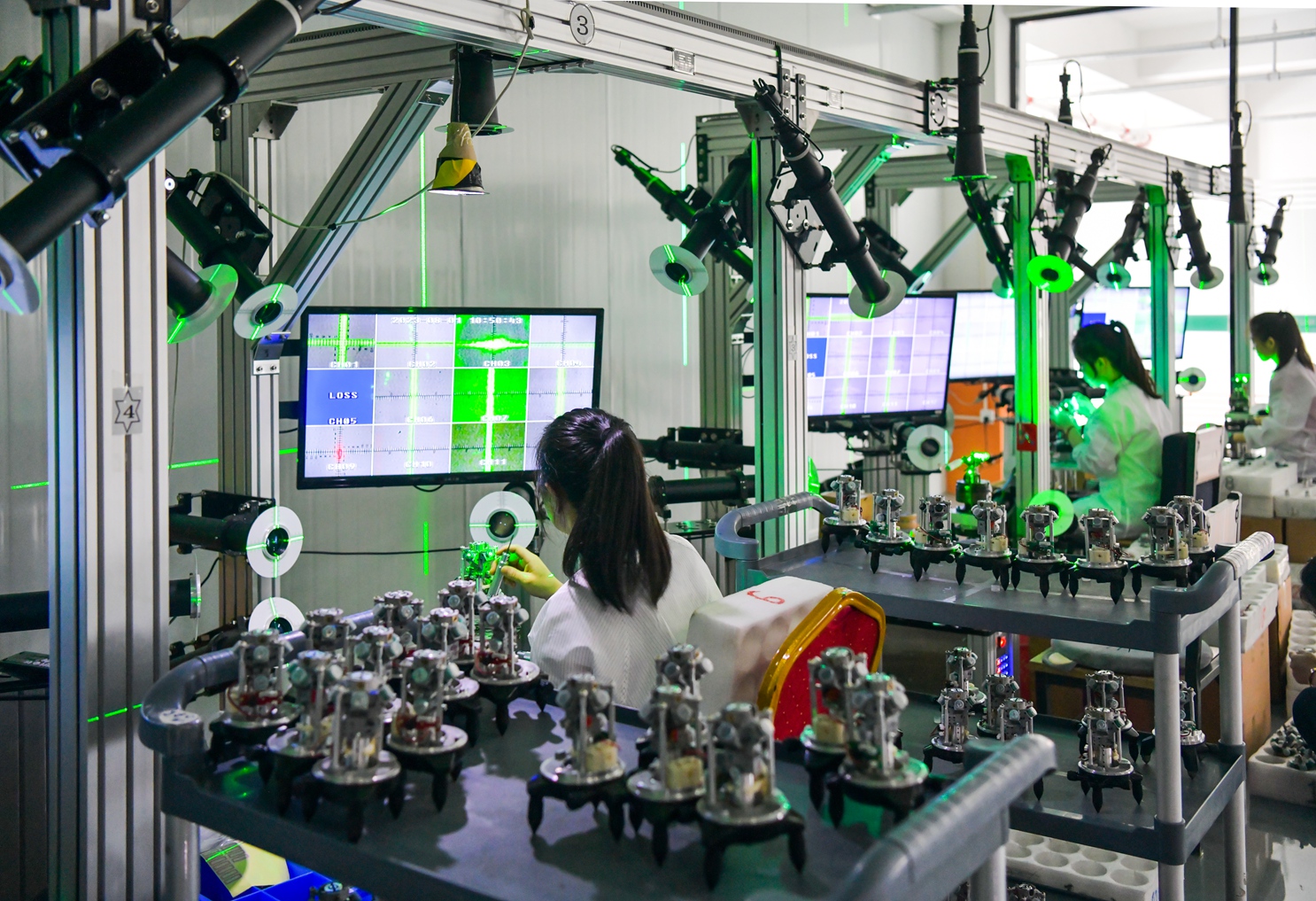

Horizontal inspection technology has an important application value in industrial production, which is mainly reflected in the following aspects:

Ensure the stability of equipment installation and operation

Equipment Installation Calibration: During the installation of various types of industrial equipment, such as large machine tools, generator sets, chemical reactors, etc., level testing is needed to ensure that the equipment is in a horizontal state. Only equipment installation level, in order to ensure the relative positional accuracy between its internal components, reduce mechanical wear and vibration caused by the installation of tilt and other problems, to extend the service life of the equipment.

Synchronization of production line equipments: In the automated production line, many equipments work together, and the horizontal detection technology can ensure that all equipments are on the same level, so that the material transmission is smooth, avoiding problems such as jamming and clogging, and ensuring the stable operation of the production line and improving the production efficiency.

Improve product quality

Ensuring production safety

Safety of large-scale equipment and building structure: In building construction and large-scale industrial equipment installation, such as the construction of high-rise buildings, the erection of large bridges, the installation of petrochemical towers, etc., level detection is a key link to ensure structural safety. Horizontal testing of building foundations, bridge piers, equipment foundations, etc. can detect problems such as uneven settlement in time, and take reinforcement or adjustment measures in advance to prevent buildings from tilting and collapsing, and to avoid the occurrence of major safety accidents.

Moving parts and track level monitoring: In some industrial equipment with moving parts, such as cranes, traveling cars, subway tracks, etc., level detection technology is used to monitor the level of the track. If there is a horizontal deviation of the track, it may lead to unstable operation of moving parts or even derailment, which may cause serious safety accidents. Through real-time level detection, track problems can be found and repaired in time to ensure the safe operation of equipment.

Realization of automated production and quality control

Feedback control of automated production line: in industrial automated production, level detection technology, as an important part of the sensor feedback system, can transmit the detected level information to the control system in real time. The control system automatically adjusts the production equipment according to this information, realizes the automated level control of the production process, improves the consistency and stability of the production, reduces the manual intervention, reduces the labor intensity and improves the production efficiency.

Quality data statistics and analysis: the data obtained from the level detection can be used as an important basis for quality control, through the statistics and analysis of a large number of level detection data, the enterprise can understand the quality fluctuations in the production process, to find out the potential quality problems and defects in the production process, for the optimization of the production process and improvement of the production process to provide data to support, so as to continue to improve the quality of products and production efficiency.

中文

中文

English

English

Online Service

Online Service