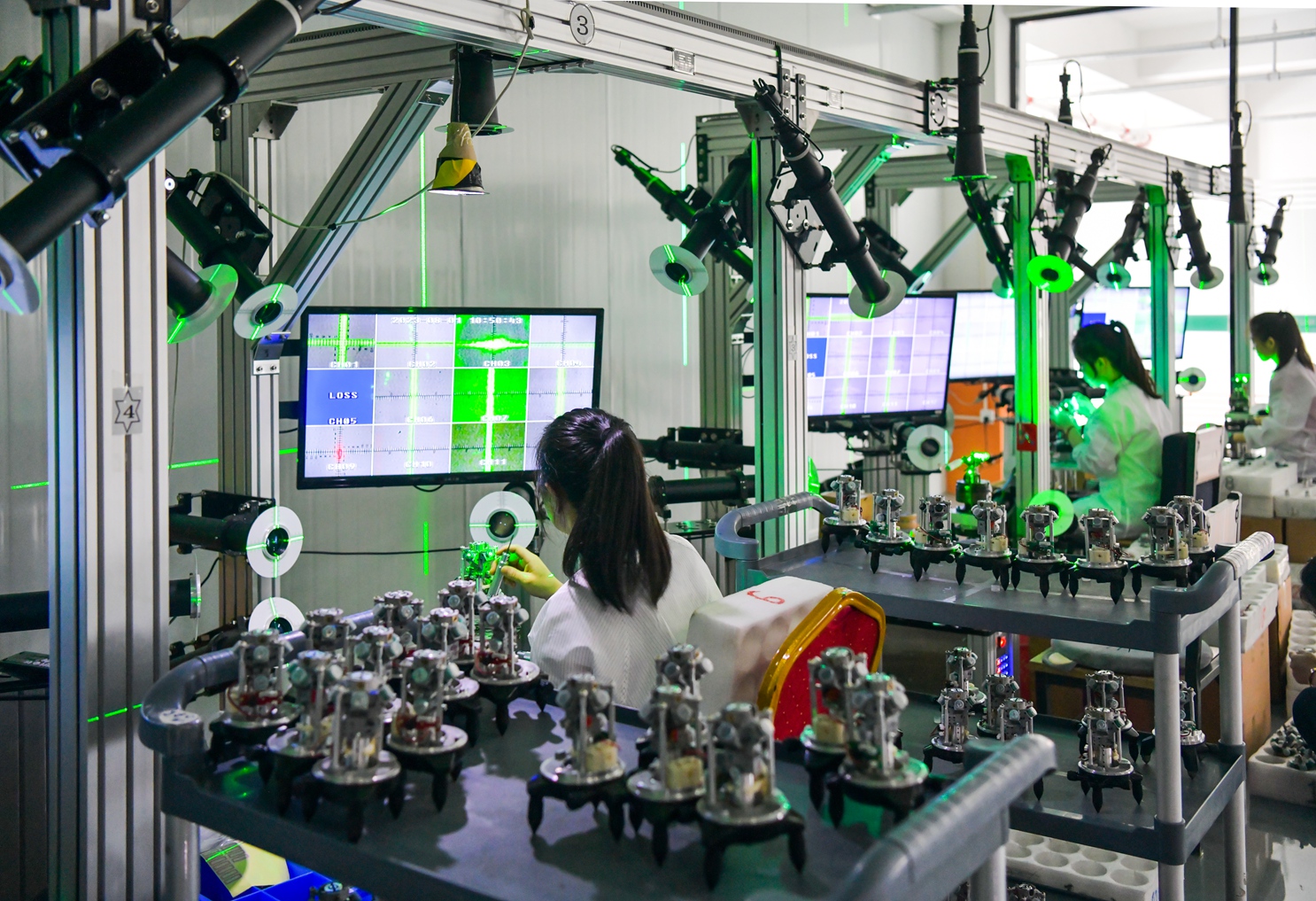

The maintenance and repair of the laser mapping instrument is crucial to ensure its measurement accuracy and extend its service life, the following are the specific maintenance and repair points:

Daily use maintenance

Pre-use inspection

Appearance check: check the surface of the instrument for bumps, scratches, cracks and other damages, whether the connection of the components is firm, whether the display, operation buttons and other normal.

Function test: turn on the instrument, check whether the laser emission is normal, whether the beam is clear and stable, whether the measurement function is accurate and whether the parameters are set correctly.

Attention in use

Correct operation: Follow the instruction manual of the instrument strictly to avoid damage to the instrument caused by illegal operation. In the process of measurement, keep the instrument stable and avoid vibration and collision.

Environmental adaptation: According to different environmental conditions, adjust the instrument parameters reasonably. For example, pay attention to the heat dissipation of the instrument in a high temperature environment; in a humid environment, prevent water vapor from entering the interior of the instrument.

Avoid direct light: Don't let the laser receiving window of the instrument directly to the strong light, so as not to affect the measurement accuracy or damage the light-sensitive components.

Cleaning after use

External cleaning: Use a soft damp cloth or special cleaning cloth to wipe the dust and stains on the surface of the instrument, for stubborn stains, a small amount of neutral cleaner can be used, but avoid the cleaner to enter the interior of the instrument.

Lens cleaning: Use lens paper or special lens cleaning solution to gently wipe the laser transmitting and receiving lens to remove dust and fingerprints, etc., to keep the lens clean and light transmittance.

Regular professional maintenance

Calibration and Accuracy Check

Regular calibration: In accordance with the recommendations of the instrument manufacturer, send the laser plotter to a professional metrology and calibration organization for calibration on a regular basis, usually once a year, to ensure the accuracy of the measurement results.

Accuracy testing: In daily use, the instrument can also be periodically tested for accuracy using objects of known standard length or angle, and if the measurement error is found to be out of the permissible range, it should be calibrated or repaired in time.

Component Inspection and Maintenance

Battery Inspection: Check the charging and discharging performance of the battery, if the battery capacity is found to be significantly reduced or charging abnormality, the battery should be replaced in time. For rechargeable battery, it should be charged according to the correct charging method to avoid overcharging or over-discharging.

Mechanical parts lubrication: For the movable mechanical parts in the instrument, such as rotating shaft, telescopic mechanism, etc., apply appropriate amount of grease on a regular basis to reduce wear and tear and ensure the flexible operation of the parts.

Electronic components inspection: Professionals can regularly open the instrument shell to check the welding of electronic components, whether there is any looseness, oxidation and other problems, if any, repair or replace them in time.

Software Update and Maintenance

Timely update: Pay attention to the software update information released by the instrument manufacturer, download and install the new software version in time to get better performance and functions, and at the same time, fix the possible software loopholes.

Data backup: Back up the measurement data in the instrument regularly to prevent data loss. Before updating the software or performing other operations that may affect the data, be sure to make a data backup first.

中文

中文

English

English

Online Service

Online Service